|

| |

|

P3HT and PCBM bilayer |

modified on

17/06/2012 |

-

-

The first single step MAPLE (ss-MAPLE) deposition of a

bilayer structure consisting of the most-studied donor-acceptor

combination for polymer solar cells, namely, the electron donating polymer

[regioregular polymer poly-(3-hexylthiophene) (P3HT) and the electron

accepting fullerene [6,6]-phenyl-C61-butyric-acid methylester (PCBM).

Furthermore, the same solvent has been used for both polymers, thus

overcoming the typical drawback of re-dissolution of the bottom layer

occurring in the conventional solution-based deposition techniques.

A polymeric solar cell based on the ss-MAPLE deposited

P3HT/PCBM heterojunction has been fabricated and characterized. The two

polymers, P3HT and PCBM (Sigma Aldrich), were both dissolved in toluene

with the weight concentration of 0.3 wt.%.

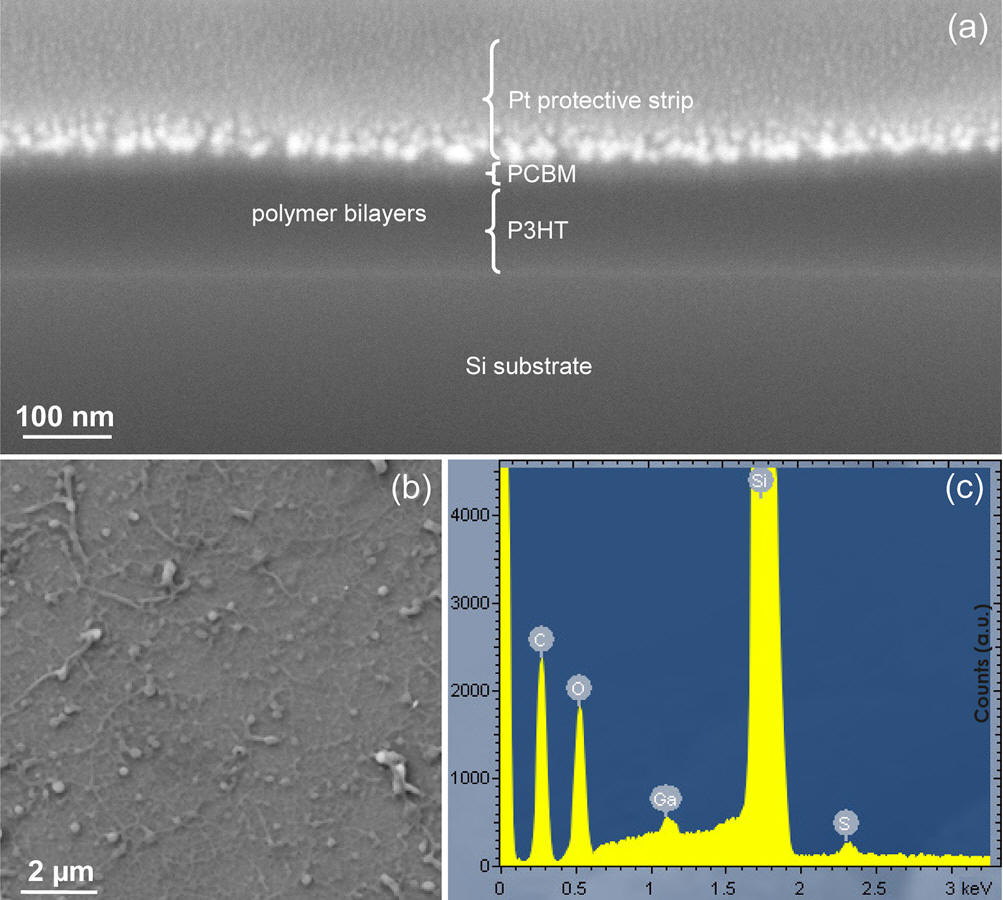

MAPLE depositions of each material were performed

using a pulsed Lambda Physik (LPX-305i) KrF excimer laser (l=248

nm, t=20 ns, pulse rate=10 Hz). To deposit P3HT and PCBM layers, 6000 and

4000 laser pulses were applied obtaining a corresponding final thickness

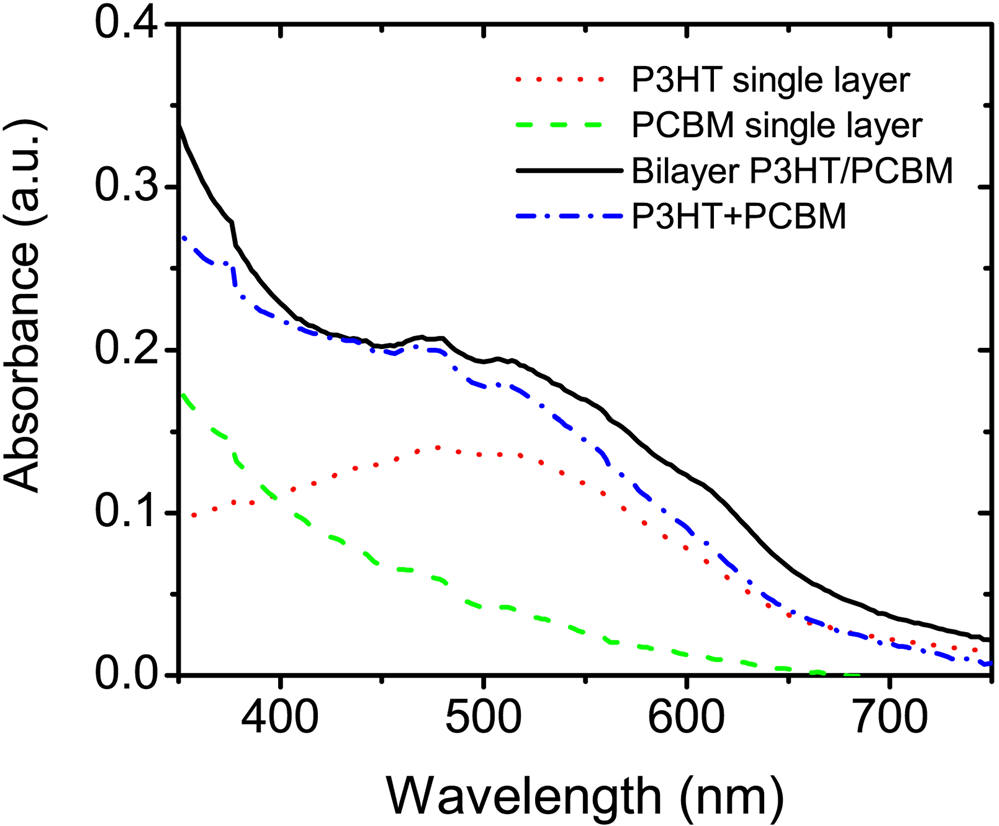

of 68 nm and 25 nm, respectively. UV-Vis absorption spectra were

acquired for the single polymer layers and for the bilayer structure,

deposited on silica slabs, using a Perkin Elmer spectrophotometer in the

wavelength range 350-750 nm with a resolution of 2 nm. Atomic force

microscopy (AFM), scanning electron microscopy (SEM), and energy

dispersive x-ray spectrometry (EDS) were used to characterize the

morphological and compositional properties of the deposited samples. In

particular, SEM and EDS analyses were performed by using a NVISION 40

Focussed Ion Beam (FIB) system equipped with a high resolution SEM Field

Emission Gun (FEG) Gemini column and an Inca Energy 350 X-ACT Oxford EDS

spectrometer.

Morphological and chemical investigations were carried

out both in plan view and cross-sectional geometry. AFM measurements were

performed in non contact mode (Park XE 70 instrument). Finally, a bilayer

solar cell was fabricated.

A

poly(3.4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT:PSS) layer

was spin-coated onto an ITO/glass substrate. Then, the active layer was

fabricated by depositing the bilayer structure onto the PEDOT:PSS layer

with 8000 laser pulses for P3HT layer (90 nm) and 4000 for PCBM layer (25

nm). To complete the device structure, LiF (0.6 nm-thick) and Al (ca.100

nm-thick) were thermally evaporated at low pressure (<1x10-6

Torr). The active area of the devices was 0.03 cm2).

Current density versus voltage (J-V) characteristics were measured using a

Keithley 2400 sourcemeter both in dark and under AM 1.5-G illumination,

filtered irradiation with an incident power of 100 mW/cm2).

All of the measurements were carried out under ambient conditions

Figure 1.

Color online) Cross-section (a), top view (b), and

EDS spectrum (c) of the P3HT/PCBM bi-layer with a 68 nm thick layer of

P3HT and a 25 nm thick layer of PCBM

UV absorption spectra of the single layers of P3HT and

PCBM and of the bilayer P3HT/PCBM, are reported in Fig. 2., thus

excluding intermixing or damaging phenomena related to the bilayer

deposition. As a preliminary application, we tested the ss-MAPLE bilayer

production in fabricating a solar cell geometry based on the configuration

ITO/PEDOT:PSS/P3HT(90 nm)/PCBM(25 nm)/LiF/Al. The PEDOT:PSS was deposited

by spin-coating according to the standard procedure for the preparation of

conventional solar cells.

Figure 2. (Color online)

UV-visible absorption spectra of the P3HT single layer (dotted line), PCBM

single layer (dashed line), and P3HT/PCBM bilayer (full line). The

arithmetical sum of the absorption spectra of the two single layer

polymers is reportedtoo (dot-dashed line).

The layered structure of the device is sketched in Fig.

3, where it is shown the current density-voltage curves (dark and

illuminated) of the fabricated bilayer. The open circuit voltage is

Voc=0.32, the short circuit current is Jsc=0.33 mA/cm2),

the fill factor is FF=28%, and PCE=0.03%. Our ss-MAPLE deposition

procedure also rules out the contamination consequences related to the

MAPLE deposition experiments of organic bilayers, already reported in the

literature.

Figure 3. Current-voltage

characteristics of the bi-layer photovoltaic device in dark (open circles)

and under one-sun illumination (AM 1.5 G; filled circles). Inset image:

Sketch of the bilayer device structure fabricated by ss- MAPLE technique.

|

| |

|