|

Film

deposition of TiO2 nanoparticles

Titanium dioxide (TiO2) is one of the most

investigated materials due to its interesting properties such as chemical

stability, non-toxicity, high refractive index, elevate dielectric constant,

anti-fog and self-cleaning abilities to be exploited in a wide range of

applications, e.g. optical coatings, electrical insulation, solar cells,

antibacterial coatings and gas sensors.

In particular, the reduction from bulk to nanostructured

material has been generally recognized as the most efficient strategy to

enhance the sensing properties of metal oxides and especially of titanium

dioxide.

In this respect, a very interesting result was obtained

since the MAPLE technique was employed, for the first time, for the

deposition of colloidal TiO2 nanoparticle thin films. In this way

it was possible to overcome the problems generally presented by the

conventional deposition techniques (spin coating and drop casting) in term

of good film thickness control and uniform coverage of flat and rough

substrates, preserving the colloidal nanoparticles properties.

Structural analyses (FTIR, XRD, EDX) revealed that TiO2

composition and crystalline phase were preserved, while optical

evaluations (UV-Vis absorbance) showed standard

responses, presented also by titania nanostructered films deposited with

other techniques.

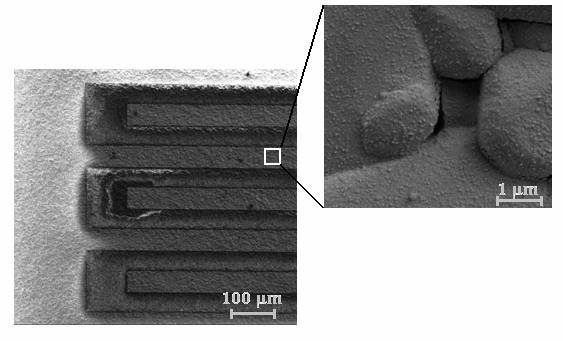

Fig. 1: Scanning Electron Microscopy images of the

interdigitated sensor and of the TiO2 film coverage on the Al2O3

grains deposited by MAPLE technique

Uniform coverage of TiO2 nanoparticles

resulted on flat silicon and quartz substrates and on non-planar alumina

substrates (Fig.1), confirming the great potentiality of this technique in

the microsensor field. In fact, these films were successfully employed as

gas detectors and integrated in a reading system. Very interesting sensing

results were achieved in terms of reproducibility and response of the sensor

in the presence of ethanol and acetone vapors.

Works are in progress to improve the thin film properties

in order to enhance the gas sensor responses and to test these devices

towards pollutant gases detection.

|